Grade 80- Grade 100

- Chain Sling Assembly

- Chain Sling Components

- Grade 80 Swivel Eye Bolt

- Grade 100 Rotating Eye Bolt

- Standard Eye Bolt

- Standard Eye Nut

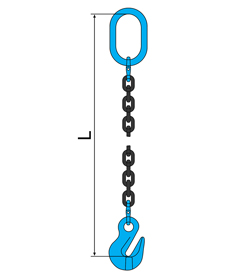

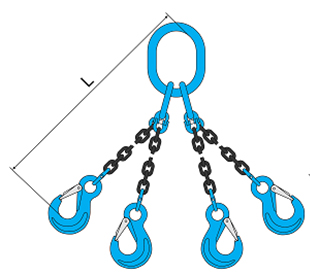

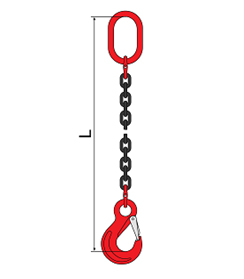

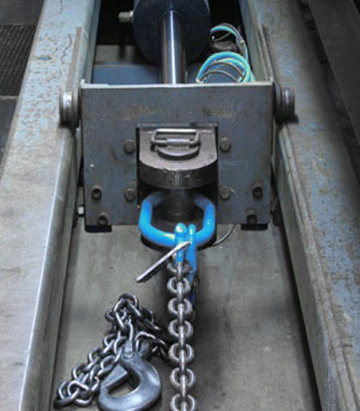

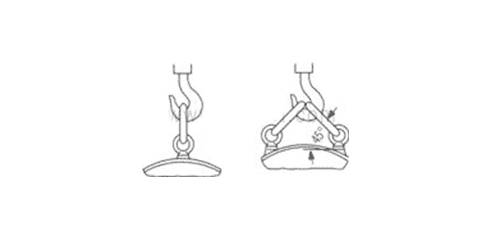

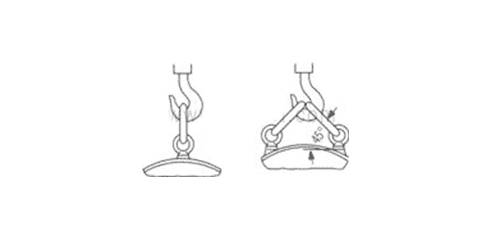

Lifting Chain Sling

All our lifting chain is custom made and certified to our customer's needs. You can build your chain to the exact specification you require by picking your own length, hooks/shortening clutch, and how many legs you require on any chain. Also available in single leg, endless, two leg, three and four leg lifting chains.

Grade 100 - 25% Stronger than Grade 80 in the same size

Grade 80

Quality Process

- 100% magnaflux tested for cracks

- Hardness tests

- Resilience tests

- Magnetoscopic tests or tests with penetrating liquide to spot surface cracks

- Tests on surface coatings

- Spectometric tests to verify chemical analyses

- Fatigue tested at 20,000 stress cycles

- Proof tested to 2.5 times the W.L.L.

- Made from high grade alloy steel. (Quenched, Tempered and proof tested)

- Components are matt blue and red finished and chains are natural black finished.

- Protected against corrosion

- Factor of Safety - 4:1 (i.e., Minimum breaking load is 4 times the W.L.L.)

- Designed, tested and certified in compliance with the technical directives GS-OA 15-04 - EN 1677 & EN818.

- Suitable for safe lifting in compliance with the machinery directive 2006/42/EC

- Marked manufacturers mark, ID mark and grade

- Permanently Embossed with marking for identification and traceability

- Lifting chains are manufactured using German WAFIOS production method, Computerized automated Knitting, Spot Welding and Calibration. So every link is Identical

- Available in 6mm, 8mm, 10mm, 13mm, 16mm, 20mm, 22mm, 26mm, 32mm

Properties

Master Ring

Stock No |

Size |

W.L.L. (Ton) |

| 151 016 AR | 6-7 mm | 1.6 ton |

| 151 020 AR | 7-8 mm | 1.12 ton |

| 151 030 AR | 8-10 mm | 3.15 ton |

| 151 050 AR | 10-13 mm | 5.3 ton |

| 151 080 AR | 13-16 mm | 8 ton |

| 151 110 AR | 16-18-19 mm | 11.2 ton |

| 151 160 AR | 18-19-20-22 mm | 16 ton |

| 151 170 AR | 20 mm | 17 ton |

| 151 250 AR | 22-26-28 mm | 25 ton |

| 151 335 AR | 26-28-32 mm | 33.5 ton |

Stock No |

Size |

W.L.L. (Ton) |

| 151 021 HB | 6-7 mm | 2 ton |

| 151 026 HB | 7-8 mm | 2.65 ton |

| 151 040 HB | 8-10 mm | 4 ton |

| 151 067 HB | 10-13 mm | 6.7 ton |

| 151 010 HB | 13-16 mm | 10 ton |

| 151 140 HB | 16-18-19 mm | 14 ton |

| 151 190 HB | 18-19-20-22 mm | 19 ton |

| 151 224 HB | 20-22 mm | 22.4 ton |

| 151 226 HB | 22-26-28 mm | 26.6 ton |

| 151 395 HB | 26-28-32 mm | 39.5 ton |

Master Ring Assembly

Stock No |

Size |

W.L.L. (Ton) |

| 151 021 HB | 6-7 mm | 2 ton |

| 151 026 HB | 7-8 mm | 2.65 ton |

| 151 040 HB | 8-10 mm | 4 ton |

| 151 067 HB | 10-13 mm | 6.7 ton |

| 151 010 HB | 13-16 mm | 10 ton |

| 151 140 HB | 16-18-19 mm | 14 ton |

| 151 190 HB | 18-19-20-22 mm | 19 ton |

| 151 224 HB | 20-22 mm | 22.4 ton |

| 151 226 HB | 22-26-28 mm | 26.6 ton |

| 151 395 HB | 26-28-32 mm | 39.5 ton |

Grade 100 |

||

Stock No |

Size |

W.L.L. (Ton) |

| 151 021 HB | 6-7 mm | 2 ton |

| 151 026 HB | 7-8 mm | 2.65 ton |

| 151 040 HB | 8-10 mm | 4 ton |

| 151 067 HB | 10-13 mm | 6.7 ton |

| 151 010 HB | 13-16 mm | 10 ton |

| 151 140 HB | 16-18-19 mm | 14 ton |

| 151 190 HB | 18-19-20-22 mm | 19 ton |

| 151 224 HB | 20-22 mm | 22.4 ton |

| 151 226 HB | 22-26-28 mm | 26.6 ton |

| 151 395 HB | 26-28-32 mm | 39.5 ton |

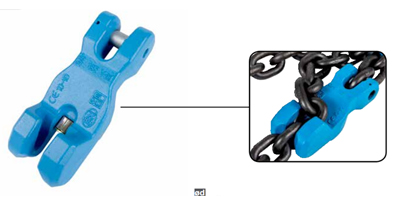

Connecting Link

Size |

W.L.L. (Ton) |

| 6 mm | 1.12 ton |

| 7-8 mm | 2 ton |

| 10 mm | 3.15 ton |

| 13 mm | 5.3 ton |

| 16 mm | 8 ton |

| 20 mm | 12.5 ton |

| 22 mm | 15 ton |

| 26 mm | 21.2 ton |

| 32 mm | 31.5 ton |

Size |

W.L.L. (Ton) |

| 6 mm | 1.4 ton |

| 8 mm | 2.5 ton |

| 10 mm | 4 ton |

| 13 mm | 6.7 ton |

| 16 mm | 10 ton |

| 20 mm | 16 ton |

| 22 mm | 19 ton |

| 26 mm | 26.5 ton |

Websling Connector

Code |

Size |

W.L.L. (Ton) |

| 191 007 8R | 8 mm | 2 ton |

| 191 010 8R | 10 mm | 3.15 ton |

| 191 013 8R | 13 mm | 5.3 ton |

| 191 016 8R | 16 mm | 8 ton |

Lifting Alloy Chain- Mid Link

Code |

Size |

W.L.L. (Ton) |

| 180 006 CN | 6 mm | 1.12 ton |

| 180 007 CN | 7 mm | 1.5 ton |

| 180 008 CN | 8 mm | 2 ton |

| 180 010 CN | 10 mm | 3.15 ton |

| 180 013 CN | 13 mm | 5.3 ton |

| 180 016 CN | 16 mm | 8 ton |

| 180 020 CN | 20 mm | 12.5 ton |

| 180 022 CN | 22 mm | 15 ton |

| 180 026 CN | 26 mm | 21.2 ton |

| 180 032 CN | 32 mm | 31.5 ton |

Code |

Size |

W.L.L. (Ton) |

| 180 006 HB | 6 mm | 1.4 ton |

| 180 008 HB | 8 mm | 2.5 ton |

| 180 010 HB | 10 mm | 4 ton |

| 180 013 HB | 13 mm | 6.7 ton |

| 180 016 HB | 16 mm | 10 ton |

| 180 020 HB | 20 mm | 16 ton |

| 180 022 HB | 22 mm | 19 ton |

| 180 026 HB | 26 mm | 26.5 ton |

Shortening Clutch

Code |

Size |

W.L.L. (Ton) |

| 185 006 HB | 6 mm | 1.4 ton |

| 185 008 HB | 8 mm | 2.5 ton |

| 180 010 HB | 10 mm | 4 ton |

| 180 013 HB | 13 mm | 6.7 ton |

| 180 016 HB | 16 mm | 10 ton |

Shortening Eye Hook

Code |

Size |

W.L.L. (Ton) |

| 183 107 AR | 8 mm | 2 ton |

| 183 110 AR | 10 mm | 3.15 ton |

| 183 113 AR | 13 mm | 5.3 ton |

| 183 016 AR | 16 mm | 8 ton |

Code |

Size |

W.L.L. (Ton) |

| 183 L07 AR | 8 mm | 2 ton |

| 183 110 AR | 10 mm | 3.15 ton |

| 183 113 AR | 13 mm | 5.3 ton |

| 183 016 AR | 16 mm | 8 ton |

Code |

Size |

W.L.L. (Ton) |

| 184 006 AR | 6 mm | 1.12 ton |

| 184 007 AR | 7-8 mm | 2 ton |

| 184 010 AR | 10 mm | 3.15 ton |

| 184 013 AR | 13 mm | 5.3 ton |

| 184 016 AR | 16 mm | 8 ton |

| 184 020 AR | 20 mm | 12.5 ton |

Code |

Size |

W.L.L. (Ton) |

| 184 L06 AR | 6 mm | 1.12 ton |

| 184 L07 AR | 7-8 mm | 2 ton |

| 184 L10 AR | 10 mm | 3.15 ton |

| 184 L13 AR | 13 mm | 5.3 ton |

| 184 L16 AR | 16 mm | 8 ton |

| 184 L20 AR | 20 mm | 12.5 ton |

Latch Hook- EYE

Code |

Size |

W.L.L. (Ton) |

| 100 107 SR | 7-8 mm | 2 ton |

| 100 110 SR | 10 mm | 3.15 ton |

| 100 113 SR | 13 mm | 5.3 ton |

| 100 116 SR | 16 mm | 8 ton |

| 100 120 SR | 20 mm | 12.5 ton |

Latch Hook- Clevis

Code |

Size |

W.L.L. (Ton) |

| 179 206 SR | 6 mm | 1.12 ton |

| 179 207 SR | 7-8 mm | 2 ton |

| 179 210 SR | 10 mm | 3.15 ton |

| 179 213 SR | 13 mm | 5.3 ton |

| 179 216 SR | 16 mm | 8 ton |

| 179 220 SR | 20 mm | 12.5 ton |

Latch Hook- Clevis

Code |

Size |

W.L.L. (Ton) |

| 179 206 HB | 6 mm | 1.4 ton |

| 179 208 HB | 8 mm | 2.5 ton |

| 179 210 HB | 10 mm | 4 ton |

| 179 213 HB | 13 mm | 6.7 ton |

| 179 216 HB | 16 mm | 10 ton |

Self Locking Hook- EYE

Code |

Size |

W.L.L. (Ton) |

| 102 006 AR | 6 mm | 1.12 ton |

| 102 007 AR | 7-8 mm | 2 ton |

| 102 010 AR | 10 mm | 3.15 ton |

| 102 013 AR | 13 mm | 5.3 ton |

| 102 016 AR | 16 mm | 8 ton |

Self Locking Hook- Clevis

Code |

Size |

W.L.L. (Ton) |

| 103 006 AR | 6 mm | 1.12 ton |

| 103 007 AR | 7-8 mm | 2 ton |

| 103 010 AR | 10 mm | 3.15 ton |

| 103 013 AR | 13 mm | 5.3 ton |

| 103 016 AR | 16 mm | 8 ton |

| 103 020 AR | 20 mm | 12.5 ton |

Code |

Size |

W.L.L. (Ton) |

| 103 006 HB | 6 mm | 1.4 ton |

| 103 008 HB | 8 mm | 2.5 ton |

| 103 010 HB | 10 mm | 4 ton |

| 103 013 HB | 13 mm | 6.7 ton |

| 103 016 HB | 16 mm | 10 ton |

Self Locking Hook- Swivel

Code |

Size |

W.L.L. (Ton) |

| 105 006 AR | 6 mm | 1.12 ton |

| 105 007 AR | 7-8 mm | 2 ton |

| 105 010 AR | 10 mm | 3.15 ton |

| 105 013 AR | 13 mm | 5.4 ton |

| 105 016 AR | 16 mm | 8 ton |

| 105 020 AR | 20 mm | 12.5 ton |

Code |

Size |

W.L.L. (Ton) |

| 106 106 AR | 6 mm | 1.12 ton |

| 106 107 AR | 7-8 mm | 2 ton |

| 106 110 AR | 10 mm | 3.15 ton |

| 106 113 AR | 13 mm | 5.4 ton |

| 106 116 AR | 16 mm | 8 ton |

| 106 120 AR | 20 mm | 12.5 ton |

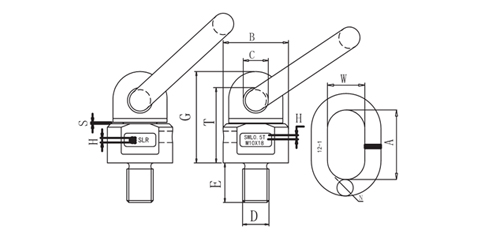

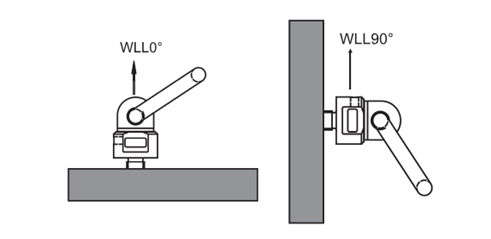

Grade 80- Forged Super Alloy Steel

Quality Testing:

- 100% magnaflux tested for cracks

- Hardness tests

- Resilience tests

- Magnetoscopic tests or tests with penetrating liquide to spot surface cracks

- Tests on surface coatings

- Spectometric tests to verify chemical analyses

- Fatigue tested at 20,000 stress cycles

- Proof tested to 2.5 times the W.L.L.

- Breakage Test

Contact us for the Customized Thread Length

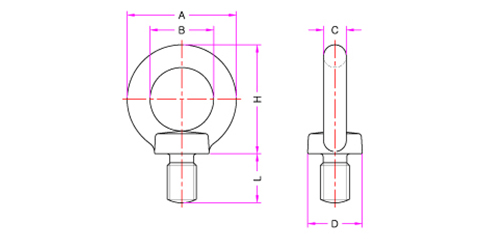

Technical Specification

Stock No |

Size |

Wll @ 90'0 |

Wll @ 0'0 |

B |

C |

G |

T |

A |

W |

N |

H |

S |

Weight |

| . | mm | t | t | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg |

| IN80-008 | M8x13 | 0,3 | 0,6 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 | 0,41 |

| IN80-010 | M10x18 | 0,5 | 0,9 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 | 0,43 |

| IN80-012 | M10x18 | 0,5 | 1,0 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 | 0,44 |

| IN80-014 | M14x20 | 1,12 | 2,0 | 36 | 16.5 | 51 | 41 | 55 | 30 | 14 | 3 | 1 | 0,45 |

| IN80-016 | M16x35 | 1,12 | 2,0 | 36 | 16.5 | 52 | 42 | 55 | 30 | 14 | 3 | 1 | 0,46 |

| IN80-020 | M20x30 | 2,0 | 4,0 | 4.95 | 19 | 68 | 56 | 70 | 35 | 16 | 3.5 | 1 | 0,96 |

| IN80-024 | M24x40 | 3,15 | 6,3 | 57 | 22 | 78 | 65.5 | 85 | 40 | 18 | 3.5 | 1.5 | 1,45 |

| IN80-027 | M27x35 | 3,15 | 6,3 | 57 | 22 | 78 | 65.5 | 85 | 40 | 20 | 3.5 | 1.5 | 1,47 |

| IN80-030 | M30x35 | 5,3 | 10,6 | 66 | 23.5 | 96.5 | 80.5 | 85 | 40 | 20 | 4 | 1.5 | 2,17 |

| IN80-036 | M36x90 | 8,0 | 11,8 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 | 4,17 |

| IN80-039 | M39x50 | 8,0 | 11,8 | 80 | 27 | 109 | 89.5 | 115 | 50 | 22 | 6 | 2 | 3,65 |

| IN80-042 | M42x50 | 10,0 | 15,0 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 | 3,62 |

| IN80-045 | M45x60 | 10,0 | 15,0 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 | 4,17 |

| IN80-048 | M48x50 | 10,0 | 15,0 | 80 | 27 | 109 | 89.5 | 115 | 50 | 25 | 6 | 2.5 | 4,02 |

| IN80-056 | M56x84 | 15,0 | 25,0 | 117 | 42 | 310 | 280 | 152 | 70 | 32 | 7 | 2.5 | 11,6 |

| IN80-064 | M64x95 | 15,0 | 25,0 | 117 | 42 | 310 | 280 | 152 | 70 | 32 | 7 | 2.5 | 12,4 |

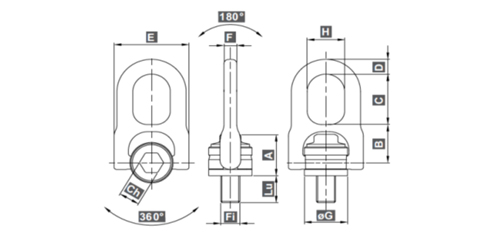

Grade 100 - (25% stronger than Grade 80)

Quality Testing:

- 100% magnaflux tested for cracks

- Hardness tests

- Resilience tests

- Magnetoscopic tests or tests with penetrating liquide to spot surface cracks

- Tests on surface coatings

- Spectometric tests to verify chemical analyses

- Fatigue tested at 20,000 stress cycles

- Proof tested to 2.5 times the W.L.L.

- Breakage Test

Technical Specification

Dimension |

Stock No. |

SIZE |

Wll @ 90'0 |

Fi |

Lu |

Ch |

A |

B |

C |

D |

E |

F |

G |

H |

Weight |

| . | . | mm | t | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg |

| . | 115 108 AY | M8x14 | 0,3 | M8 | 14 | 17 | 32 | 32 | 40 | 11 | 54 | 9 | 30 | 29 | 0,31 |

| . | 115 110 AY | M10x17 | 0,6 | M10 | 17 | 17 | 32 | 32 | 40 | 11 | 54 | 9 | 30 | 29 | 0,32 |

| . | 115 112 AY | M12x21 | 1 | M12 | 21 | 17 | 32 | 32 | 40 | 11 | 54 | 9 | 30 | 29 | 0,33 |

| . | 115 116 AY | M16x27 | 1,6 | M16 | 27 | 22 | 46 | 42,5 | 56 | 16,5 | 78 | 13,3 | 45 | 39 | 1,00 |

| . | 115 120 AY | M20x30 | 2,5 | M20 | 30 | 22 | 46 | 42,5 | 56 | 16,5 | 78 | 13,3 | 45 | 39 | 1,05 |

| . | 115 124 AY | M24x36 | 4 | M24 | 36 | 32 | 63 | 59 | 85 | 25 | 119 | 20 | 60 | 60 | 3,00 |

| . | 115 130 AY | M30x45 | 6,3 | M30 | 45 | 32 | 63 | 59 | 85 | 25 | 119 | 20 | 60 | 60 | 3,10 |

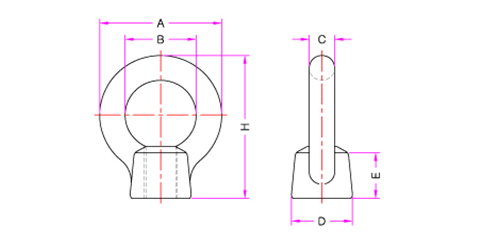

Eye Bolt Din Standard 580

Technical Details

Maximum loadings by the piece lifted in kg |

||||||||||

| 1 | M6 | 27.5 | 12 | 27 | 19 | 14 | 6.5 | 0.055 | 0.7 | 0.5 |

| 2 | M8 | 36 | 13 | 36 | 20 | 20 | 8 | 0.06 | 0.14 | 0.95 |

| 3 | M10 | 45 | 17 | 45 | 25 | 25 | 10 | 0.1 | 0.23 | 0.17 |

| 4 | M12 | 53 | 20.5 | 54 | 30 | 30 | 12 | 0.19 | 0.34 | 0.24 |

| 5 | M14 | 62 | 27 | 63 | 35 | 35 | 14 | 0.25 | 0.49 | 0.34 |

| 6 | M16 | 62 | 27 | 63 | 35 | 35 | 14 | 0.31 | 0.7 | 0.5 |

| 7 | M18 | 71 | 30 | 72 | 40 | 40 | 14 | 0.36 | 0.9 | 0.65 |

| 8 | M20 | 71 | 30 | 72 | 40 | 40 | 16 | 0.45 | 1.2 | 0.83 |

| 9 | M22 | 90 | 36 | 90 | 50 | 50 | 20 | 0.68 | 1.5 | 1.05 |

| 10 | M24 | 90 | 36 | 90 | 50 | 50 | 20 | 0.72 | 1.8 | 1.27 |

| 11 | M27 | 109 | 45 | 108 | 65 | 60 | 24 | 1.16 | 2.5 | 1.65 |

| 12 | M30 | 109 | 45 | 108 | 65 | 60 | 24 | 1.6 | 3.6 | 2.6 |

| 13 | M33 | 128 | 54 | 126 | 75 | 70 | 28 | 2 | 4.3 | 3.2 |

| 14 | M36 | 128 | 54 | 126 | 75 | 70 | 28 | 2.8 | 5.1 | 3.7 |

| 15 | M42 | 147 | 63 | 144 | 85 | 80 | 32 | 4.2 | 7 | 5 |

| 16 | M45 | 168 | 68 | 166 | 100 | 90 | 38 | 5.3 | 8 | 5.5 |

| 17 | M48 | 168 | 68 | 166 | 100 | 90 | 38 | 6.5 | 8.6 | 6.1 |

| 18 | M52 | 187 | 78 | 184 | 110 | 100 | 42 | 7.4 | 9.9 | 7.3 |

| 19 | M56 | 187 | 78 | 184 | 110 | 100 | 42 | 7.9 | 11.5 | 8.3 |

| 20 | M64 | 208 | 90 | 206 | 120 | 110 | 48 | 8.5 | 16 | 11 |

| 21 | M72 | 260 | 100 | 260 | 150 | 140 | 60 | 9 | 21 | 15 |

| 22 | M80 | 298 | 112 | 296 | 170 | 160 | 68 | 10.2 | 28 | 20 |

| 23 | M100 | 330 | 130 | 330 | 190 | 180 | 75 | 11.5 | 38 | 27 |

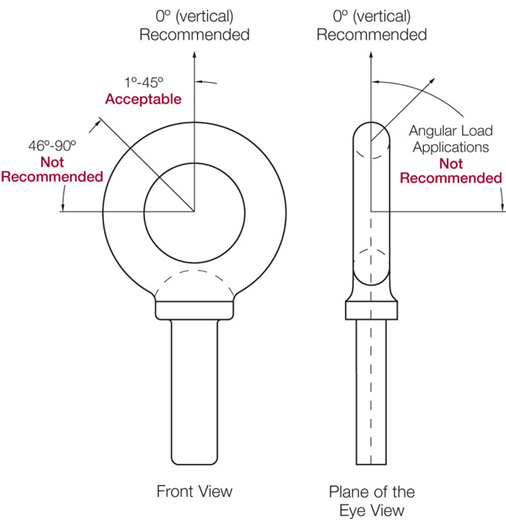

Inspection/Maintenance Safety:

- 1. Always inspect eye bolt before use.

- 2. Never use eye bolt that shows signs of wear or damage.

- 3. Never use eye bolt if eye or shank is bent or elongated.

- 4. Always be sure threads on shank and receiving holes are clean.

- 5. Never machine, grind or cut eye bolt.

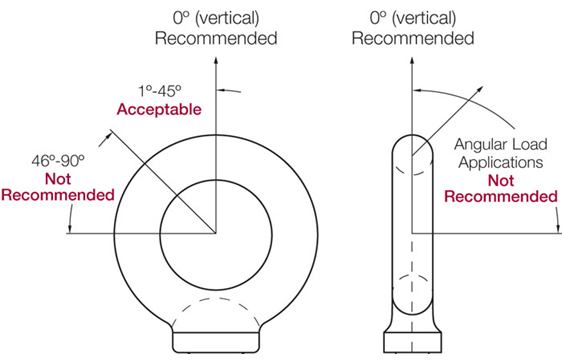

Direction of Pull (in-line) |

Adjusted Work Load |

| 45 degrees | 30% of Work Load Limit |

| 90 degrees | 25% of Work Load Limit |

Assembly Safety:

- Never exceed Work Load Limits specified in Tables 1 & 2.

- Never use regular nut eye bolts for angular lifts.

- Always use shoulder nut eye bolts (or machinery eye bolts) for angular lifts.

- For angular lifts, adjust Work Load as follows:

Eye Nut Din Standard 582

Technical Details

Maximum loadings by the piece lifted in kg |

||||||||||

| 1 | M6 | 36 | 28 | 16 | 17 | 6.5 | 0.04 | 0.055 | 0.07 | 0.05 |

| 2 | M8 | 36 | 36 | 20 | 20 | 8 | 0.08 | 0.06 | 0.14 | 0.11 |

| 3 | M10 | 45 | 45 | 25 | 25 | 10 | 0.15 | 0.1 | 0.23 | 0.17 |

| 4 | M12 | 53 | 54 | 30 | 30 | 12 | 0.22 | 0.19 | 0.34 | 0.24 |

| 5 | M14 | 53 | 54 | 30 | 35 | 12 | 0.33 | 0.25 | 0.49 | 0.34 |

| 6 | M16 | 62 | 63 | 35 | 35 | 14 | 0.45 | 0.31 | 0.7 | 0.5 |

| 7 | M18 | 71 | 72 | 40 | 40 | 16 | 0.5 | 0.36 | 0.9 | 0.63 |

| 8 | M20 | 71 | 72 | 40 | 40 | 16 | 0.55 | 0.45 | 1.2 | 0.83 |

| 9 | M22 | 80 | 81 | 45 | 50 | 20 | 0.63 | 0.68 | 1.5 | 1.05 |

| 10 | M24 | 90 | 90 | 50 | 50 | 20 | 0.79 | 0.72 | 1.8 | 1.27 |

| 11 | M27 | 90 | 90 | 50 | 50 | 24 | 0.95 | 1.16 | 2.5 | 1.75 |

| 12 | M30 | 109 | 108 | 65 | 60 | 24 | 1.5 | 1.6 | 3.2 | 2.6 |

| 13 | M33 | 128 | 126 | 75 | 70 | 28 | 2.3 | 2 | 4.3 | 3.1 |

| 14 | M36 | 128 | 126 | 75 | 70 | 28 | 3.4 | 2.8 | 4.6 | 3.7 |

| 15 | M42 | 147 | 144 | 85 | 80 | 32 | 4.5 | 4.2 | 6.3 | 5 |

| 16 | M45 | 168 | 166 | 100 | 90 | 38 | 6.5 | 5.3 | 8 | 6.4 |

| 17 | M48 | 168 | 166 | 100 | 90 | 38 | 9 | 6.5 | 8.6 | 6.1 |

| 18 | M52 | 187 | 184 | 110 | 100 | 42 | 15 | 7.4 | 8.6 | 6.1 |

| 19 | M56 | 187 | 184 | 110 | 100 | 42 | 20 | 7.9 | 11.5 | 8.3 |

| 20 | M64 | 208 | 206 | 120 | 110 | 48 | 30 | 8.5 | 16 | 11 |

Inspection/Maintenance Safety:

- 1. Always inspect eye bolt before use.

- 2. Never use eye bolt that shows signs of wear or damage.

- 3. Never use eye bolt if eye or shank is bent or elongated.

- 4. Always be sure threads on shank and receiving holes are clean.

- 5. Never machine, grind or cut eye bolt.

Direction of Pull (in-line) |

Adjusted Work Load |

| 45 degrees | 30% of Work Load Limit |

| 90 degrees | 25% of Work Load Limit |

Assembly Safety:

- Never exceed Work Load Limits specified in Tables 1 & 2.

- Never use regular nut eye bolts for angular lifts.

- Always use shoulder nut eye bolts (or machinery eye bolts) for angular lifts.

- For angular lifts, adjust Work Load as follows:

INNOSOL Lifting Private Limited is dedicated to cater the needs of Material Handling & Industrial Equipments for Wind Energy, Automobile, Heavy Machinery, Dies & Moulds, Steel etc,. We based at Chennai - the industrial hub of South India, having our office at Perungalathur, Chennai.